Woodhead - the Boring bit

Construction work on the third Woodhead tunnel started in February 1949. This was to be lined throughout with a minimum of 21" (53cms) of concrete and the design incorporated all the necessary overheads for the completion of the electrification of the Sheffield-Wath-Manchester line. Authority to proceed with the works was granted by the newly-constituted Railway Executive on 15th November 1948. The Parliamentary survey (for the LNER 1947 Act) had taken place in the notoriously harsh Winter of 1946/7 when certain normally prominent landmarks needed to be located under deep snowdrifts using ranging rods. This was the same winter when traffic on the similarly exposed Settle-Carlisle line was disrupted for a number of weeks and on at least one occasion an engine was completely engulfed in snow (Dent cutting) and had to be dug out by hand.

The contract was let to the contractors who had worked on the repairs to the old twin bore tunnels, Messrs Balfour Beatty, but differed from the orthodox form of contract. What was agreed upon was that the work be carried out on a target basis, with a fixed fee for the contractor with adjustments according to the relationship between actual and target costs. The difficulties which were encountered during the construction (and which had seemingly been envisaged by various contractors who were initially invited to tender) were deemed to justify this departure from the orthodox.

The eventual contractor did have the benefit of what must have initially seemed a God-send. The Engineer in charge of the second of the single line tunnels, Mr W A Purdon, had deposited a large and detailled longitudinal section of the old tunnels (and the five airshafts) with the Geological Museum, South Kensington. This had been made in 1845 and may well have been instrumental to some degree in the forming of the unorthodox contract, although I can find no record of this as such. Regretably, there were no technical records to be found of the detail of planning and execution of the previous tunnels.

Design

The original tunnels were each driven, respectively, from their two portals and from the (same) five shafts, with those shafts being retained for ventilation (not wholly successfully, as it transpired, as only two regularly acted as updraught shafts and the other three usually as down-draught). Because the line was concurrently being electrified throughout and with the greater cross-section of the tunnel, it was decided that ventilation was not of particular importance. The new tunnel was thus planned to be driven from the two portals and intermediate shafts for constructional needs only. The Engineer's plans called for three of these, but the Contractor's alternative proposals called for a single shaft.

These proposals were accepted, but it was then decided to provide a ventilation facility near the gradient peak. Thus a 45° stope, 8 feet in diameter, was driven to connect with the existing No. 5 shaft. The working shaft, however, was 16 feet diameter, and sited 25 feet 6 inches from the centre-line of the new tunnel on the south side. The thinking here was that it would provide:-

- hoisting arrangments clear of the tunnel operations.

- ventilation clear of the running lines, which also precluded any danger from objects being dropped down the shaft. (Those who know the location may feel that this was 'overkill' as the surface site is well past 'the middle of nowhere' en route to the 'back of beyond').

The Contractor's plan called for a single construction shaft to drive the pilot tunnel but to drive the full diameter only from the portals. This called for re-planning of the disposition of the spoil disposal sites. The initial 1947 Act had been quite firm on the requirements for this, and those charged with preserving the amenities of the countryside were "firm in their demands regarding the disposal of the spoil but, with a spirit of give-and-take on both sides, agreement was reached and the spoil heaps today present a very acceptable appearance". (53 years after the opening of the thrid tunnel, these spoil heaps are still marked on Ordnance Survey maps [as 'Tip - disused'] and frankly are indistinguishable from the surrounding countryside even when you know where they are). No figures were ever available for the achievement of this 'near-perfection' but obviously extra costs were involved and questions were certainly asked regarding the country's ability to pay relative to the development. Had questioners know the fate of the tunnel after a very short span of time, the questions may have been asked ever more seriously!

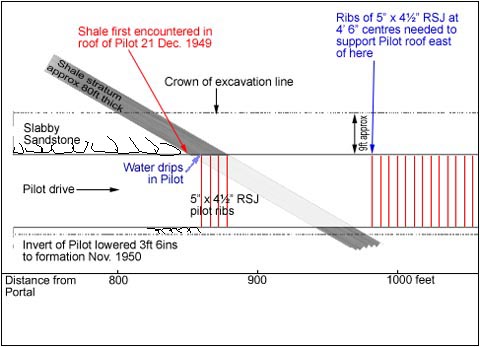

Detail of change in nature of ground at Woodhead end,

discovered during Pilot tunnelling.

Construction

The Contractor planned to drive a 12 foot by 12 foot pilot tunnel from each portal and from the construction shaft. Enlargement to full section was to be made entirely from the two portals. The proposal was that the pilot bore would be enlarged by radial rather than face drilling. This seemingly elegant proposal meant that the drilling gangs could work continuously, being supplied through the pilot tunnel from the central shaft and with spoil being removed behind them by te 'mucking' gangs. By giving the drilling gangs an appropriate 'head start', the following gangs could charge the holes and blow the enlargement, followed by spoil removal through the enlarged tunnel. By this means, it was anticipated that targets of 80 feet for each of the four faces of the pilot tunnel, followed by 120 feet per week for enlargement by radial drilling were readily achievable and that the target of 42 months specified could be met. That was the plan!

Oh, blast!

In this particular rock, radial drilling proved completely impractical and the entire system had to be abandoned. The problem was that the charges blew a completely uncontrollable section, with either considerable overbreak (which would have had to be back-filled) or insufficient break which entailed extensive trimming to achieve the profile. No method could be devised around this, while still using radial drilling and the technique had to be abandoned completely.

The classical method of hard-rock tunnelling, face drilling, allows holes to be disposed to remove a central wedge of rock, then ease out the bulk of the rock and finally roughly cut the perimeter to an acceptable profile. However, it also means that drilling, charging/firing and clearing cannot take place simultaneously.

Radial enlargement, on the other hand, requires certain characteristics in the rock being worked which proved not to be relevant in this case. Retrospective wisdom may question the feasibility of even considering radial drilling but the results were not foreseen and the advantages in terms of progress speed and cost would have been considerable. Indeed, the report to the Institute of Civil Engineers alludes to this with the statement that 'it would be of great interest to see the results of radial drilling in close-grained rock, where the disadvantages of a roughly cut profile (and consequent overbreak) might well be outweighed by the resulting economy in time and manpower'. A balancing act; on the one hand a controlled but costly method, on the other a more risky but cost effective method. But it all depends on the rock.

Rock

The problems encountered driving the third Woodhead tunnel were mainly down to the rock. Millstone grit (a coarse form of sandstone) and argillaceous shale were both encountered - with the 'doubtful' shale forming almost three-quarters of the length to be driven through. The planned enlargement speed of 120 feet per week dropped dramatically to an expectation of 20 to 30 feet per week. Clearly time targets were not going to be met by a very large margin.

Abandoning radial drilling in itself created organisational problems - there were only four possible working faces for enlargement, one third the number used a century before for smaller cross-section tunnels. Because of awkward working conditions at the portals, it was deemed impractical to start full-face working directly from outside. What was needed was an increased number of drilling faces.

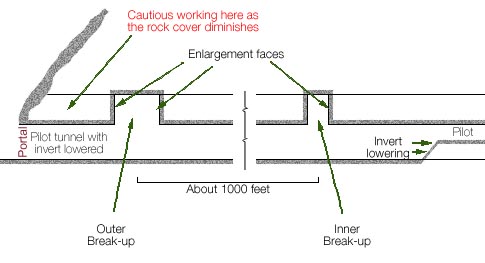

Invert lowering and Breakup from the pilot tunnel (Woodhead end)

The pilot tunnel had been driven with the invert actually 3½ feet above the invert of the finished tunnel. Before any works traffic could pass from the enlargement faces to the main tunnel behind, the invert had to be lowered to finished level. Once this had progressed to give working clearance, enlargement chambers were created to provide additional working faces. Work progressed on lowering the pilot invert with the enlargement faces effectively playing 'catch-up' behind them. This in itself created problems as the spoil from the invert lowering further inside the tunnel had to be removed past the enlargement chamber(s) and further delays were inevitable. Yet a further consideration was that a heavy fall at one of the enlargement faces could result in the inner gangs being cut off.

If it had been possible to work to a rigid timetable, scheduling traffic and services interruptions to minimise disruption, work might have progressed at an acceptable rate. In practice, both gangs struggled with difficult ground conditions and any 'timetable' was impossible to operate. But for a disastrous roof fall at this stage, one may wonder how the problem would have been solved.

All fall down.

The section in question was relatively small. Engineers had found that sections through sandstone stood without further support while those through the shale needed steel ribs. This had been anticipated, planned for and costed. What had not been anticipated was the sheer number of steel supports needed - both because they needed to be more closely spaced than anticipated and also because a greater number of sections needed support. In June 1951, with a few scant hours warning, a 72 foot length of the already enlarged tunnel close to the Woodhead end collapsed. Eventually, after the collapse of six reinforcing ribs, this roof fall extended for 100 feet. The magnitude of this fall can be measured by the fact that it took 6 months to clear! The void left after clearing the roof fall was over 70 feet in a vertical wedge above the finished invert level. Then, at the Dunford Bridge end, there were signs of similar load being placed on the enlarged tunnel. The load seemed to develop about three weeks after excavation. Here, fortunately, the symptoms were recognised and supports were put in place before another fall. In itself, this was both difficult and dangerous, and one fatality occurred.Effectively, the boring of the third Woodhead tunnel was now down to a single portal through which any spoil had to be removed, with consequent disruption to drilling, blasting and mucking. At this moment, 42 months for completion must have started to look like hugely optimistic.

Another result of this roof fall came in the design of the gantry used for the face drilling. When it became obvious that support ribs were to be the norm, rather than exceptional, facility for the fitting of the ribs immediately after drilling was incorporated into the drilling gantry. In the greater part of the tunnel, it became apparent that the closeness of the drilling and rib-placement operations was vital in preventing further falls. In general, the ribs were placed 4ft 6ins apart.

Stand and deliver.

If you travel down Longdendale now, in late 2007, you come across many signs demanding a bypass - Stand and Deliver being the slogan adopted. The news is that one, indeed several, bypasses were built two generations ago. Not that they would have done anything for present day road congestion in the form they took (and they were several miles further up the valley anyway), but they certainly did something for post-war tunnel congestion!

When the extent of the Woodhead end fall became apparent, and the fact that it would be many months before either that working face or the recently started expansion chamber could be accessed, it was decided to build a haulage way round the obstruction. A bypass! This was so successful that eventually almost 9,500ft of bypass tunnel was built 60 feet south of the pilot tunnel and with access formed whever required. At the Dunford Bridge end, another bypass was formed about 600 feet from the portal and what had been an expedient work-round of a problem actually became the solution to the access problem with up to 9 enlargement faces in operation.

Ribbing.

There is a tendency for the layman, myself included, to think of tunnelling as being boring through solid rock. Far from it, certainly in this case. The first 800+ feet were indeed through blocky sandstone at the Woodhead end, at which point the argillaceous shale inclined at 30° started to appear in the roof of the pilot bore about 850ft in from the Woodhead end. A stratum about 80 feet thick, inclined at 30° from the horizontal, appeared in the roof of the pilot tunnel - first encountered on 21 December 1949. 5ins x 4½ins RSJ pilot ribs were installed to support the pilot roof, where water drips were encountered from the shale. Starting just short of the 1000ft mark (from Woodhead), 5ins x 4½ins RSJ ribs were found to be needed eastwards to support even the pilot roof. Subsequently, considerable argument raged about the use of so much steel in a country at that time starved of the raw materials. This argument was waged in collar and tie far from the scene of the ribbing - one rather pithy response was that "he (the respondent) had found from his experience of supervising the contract from his London office that when criticism was attempted from the top stage of the gantry at the face, rather than from safer situations, it was apt to undergo modification!". How easy it must be to pontificate far removed from the possibility of half the Pennines falling on your head, and how neatly that very point was made. Criticism of the way in which the supports were placed was acknowledged - it was agreed that the roof packings were far from ideal, but that it should be remembered that they were thrust in hurriedly by men working as best they could under unsupported rock of a very unreliable nature and that often it was a matter of getting something in quickly at all costs. The thought of all that unsupported roof, particularly remembering that shale is hardly the most stable of materials, must have concentrated the mind most wonderfully.Background to this, and less well reported than many other matters, is that during the inspection of the second of the single bores. the Government Inspector noted a bulging in the wall of the tunnel (which had, it should be remembered, been stone lined) which in his opinion meant that the tunnel was unsafe and unfit for use. The second tunnel was not passed for use until this bulge had been removed and the lining restored. So the nature of the ground was not a new problem.

As far as criticism of the use of so much steel is concerned, and about 5900 tons were used and left in place, it should be noted that a good proportion of this was actually recycled (not the term used then, of course, but a modern buzz-word) tram-line which had been removed from countless locations and was at that time redundant.

Looking back.

Mention was made earlier of the existence of a longitudinal section through the old tunnel and shafts which at least gave an indication of the sort of terrrain being worked. One completely unknown factor was the effect which the old tunnels had had on the water-bearing capacity of the land. Had the old tunnels drained the surrounding rock to a lesser water content than would otherwise be the case? Had the blasting and driving of the two old tunnels set up stresses in the surrounding rock through which the new tunnel was to be driven? In some ways, the old record could possibly be misleading.Contemporary reports suggest that the bidding contractors, especially those tendering on terms at variance with the originally requested ones, were to some extent aware of the nature of the problem and had taken this into account as far as possible. Not everything can be accurately assessed beforehand, though. In the eventual making of the by-pass adits, especially at the Dunford Bridge end, so much had the ground changed even from that found in the new workings, that soft-earth tunnelling techniques were found to be better suited. Completely different from what was at first anticipated!

Research on this feature is ongoing.

Please watch this space!

Information on the twin tunnels can be found in " Woodhead - the twin tunnels "

The background to Woodhead 3 can be found in " Woodhead - the Third tunnel "

- - - © 2007 Philip Weston - - -